Sensory Science Group (SS), Biological Reference Laboratory Center (BRLC)

Fig 1. Puffed snack with cricket protein from an extruder.

Fig 3. Instant Wolffia drink.

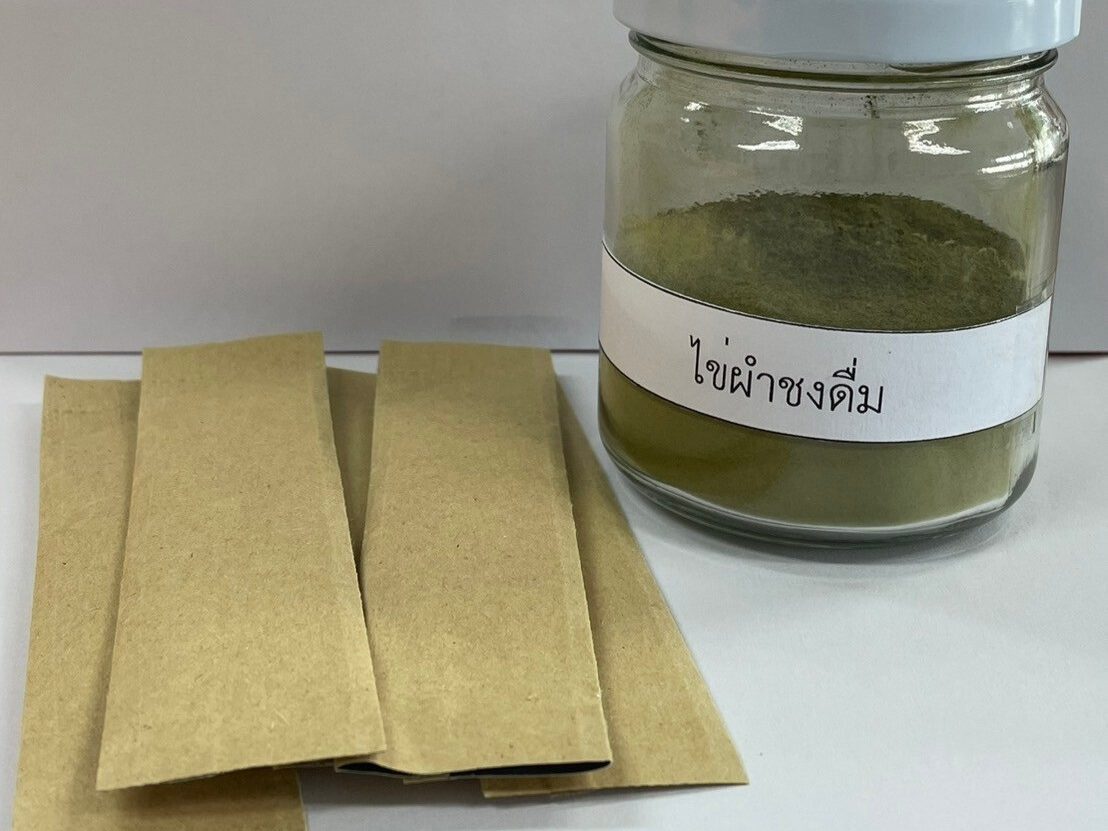

Fig 2. Instant cricket drink.

Fig 4. Kai Algae jelly.

✨ 1. Significant Products:

Currently, global food consumption trends are rapidly evolving, with increasing emphasis on health, environmental sustainability, and food safety. One of the most prominent trends is “alternative proteins”, which are sources of protein that do not come from traditional animal meat. These may be derived from plants (plant-based proteins), microorganisms (microbial proteins), algae (algae-based proteins), or insects (insect proteins), as well as proteins produced using biotechnological innovations, such as cultured meat. Research in alternative proteins plays a crucial role in developing innovative food products that are highly nutritious, have taste and texture similar to animal-based products, and meet the expectations of modern consumers.

The Sensory Science Group has been conducting research and development on alternative protein food products by integrating knowledge from food processing technology, food chemistry, sensory science, and consumer behavior insights to create high-quality products that align with consumer needs and preferences.

- Instant Wolffia Drink Powder contains 1.75% Wolffia, combined with maltodextrin and water. The production process begins with drying fresh Wolffia using a hot-air oven at 55°C until completely dry, followed by grinding into a fine powder. The resulting powder is dissolved in boiling water and stirred for 5 minutes, then filtered through a muslin cloth. Maltodextrin is added, and the mixture is stirred for an additional 10 minutes. The mixture is then dried again using a hot-air oven at 55°C until the moisture content is reduced to below 4%, and finally ground into a fine powder once more. The finished product is well-suited for preparing as a beverage, offering an appealing aroma and taste that has been well accepted by the target consumer group. Moreover, it retains the full nutritional value of Wolffia.

- The puffed snack with cricket protein is produced by using a single-screw extrusion process. The formulation contains 15–18 % of cricket powder along with other ingredients including milled rice flour, seasoning powder, oil, and water (the moisture content of the raw mixture is adjusted to 14–15%). The mixture is shaped using a single-screw extruder, which processed through various production stages. The extruded product is cut at the circular die in the last step, forming round puffed strands approximately 10 cm in length and 0.5 cm in diameter. Following extrusion, the product undergoes a drying process in a hot-air oven at 70°C for 2 hours to reduce moisture content. The final product is a crispy, high-protein puffed snack with enhanced nutritional value, offering both appealing texture and health benefits.

- Instant Cocoa-Flavored Cricket Beverage Mix uses high-protein cricket powder as its main ingredient. The process begins by roasting the crickets over low heat to eliminate their distinctive odor and develop a pleasant aroma. The roasted crickets are then blended with other ingredients, including finely ground roasted cashew nuts, cocoa powder, sucralose, CMC (a thickening agent), and synthetic flavoring. The result is a rich, smooth-tasting beverage mix that is easy to drink and features a creamy note from the cashew nuts. The product is packaged in tightly sealed sachets to maintain its quality and freshness.

🏢 2. Responsibilities of Group:

- Conduct research and development of advanced and precise sensory science testing methodologies to serve as national reference standards.

- Prepare and provide certified reference materials related to sensory science to support testing and quality control activities in both public and private laboratories.

- Evaluate the sensory properties of goods and products by sensory science as a nationally recognized reference laboratory, ensuring compliance with international standards and legal requirements.

- Establish and maintain laboratory quality management system in accordance with ISO/IEC 17025 together with conducting other relevant safety and quality standards.

- Disseminate knowledge to personnel in government organizations and industrial sectors to enhance capabilities in testing and quality control.

- Establish networks in academic, research and development, and transferring innovation and technology for commercial application in partnership with relevant national and international organizations.

- Collaborate with relevant organizations to formulate regulations and standards at both national and international levels.

- Support research and development of scientific and technological standards, and promote the capacity building of network laboratories and industrial sectors to enhance the country’s competitiveness at the international level.

- Coordinate and support tasks assigned by relevant organizations or delegated by supervisory authorities.

🎯 3. Scope of Research Field:

The Sensory Science group focuses on research related to food product development, the development of analytical methods for key compounds, flavor and aroma substances, and functional ingredients. The group also emphasizes the application of scientific instrumentation and sensory evaluation in product development and quality control. The research activities are supported by national funding agencies. Upon completion of the research projects, the team has actively transferred the acquired knowledge and developed technologies to relevant stakeholders including entrepreneurs, government agencies, and the private sector through hands-on training workshops, user manuals, and in-depth technical consultation. These efforts aim to promote the commercialization of research outcomes and enhance the competitiveness of the industry. In addition, the research findings have been disseminated through publications in both national and international journals.

🧪 4. Related Testing/Calibration:

–

🥼 5. Testing Services:

🔬 6. Key Scientific Instruments/Techniques:

🏆 7. Outstanding Achievements/Awards and Honors:

- The laboratory for testing aroma components in food is a partner in the mutual recognition arrangement of the laboratory assessment and accreditation system through peer evaluation under the National Research Council of Thailand (NRCT).

- Alternative proteins are classified as foods of the future, and the alternative protein industry has grown rapidly due to the global population increasing at a faster rate than food production. Urban expansion, intensive use of natural resources, escalating land use changes, and rising consumption of meat—such as beef and pork—are all contributing factors. As the demand for protein increases while natural resources dwindle, it has become essential to find more sustainable and safe food sources to meet global market needs. This research focuses on the development of insect-based protein by creating insect noodles, aiming to enhance the value of edible insects. These noodles can be commercially produced and marketed by food entrepreneurs.

Fig 1. Lab Safety from NRCT.

Fig 2. Spicy basil with small insect noodles.

Fig 3. Cream with small insect noodles.

Fig 4. Tomato with small insect noodles.

📄 8. Reference publications/Journal:

Jiraporn Burakorn, Pran Pinthong, Panuwat Dangsungnoen, Montakan Aimkaew and Grianggrai Nakages, Development of Salted Egg Powder Product, Proceeding the 20th Food Innovation Asia Conference, 14-16 June 2018, BITEC Bangna, Bangkok, Thailand, 2018.

Jiraporn Burakorn, Pran Pinthong and Montakan Aimkaew, Development of Healthy Seasoning Pork Rind Product, KKU Science Journal. 49(3): 274-282, 2021.

https://ph01.tci-thaijo.org/index.php/KKUSciJ/article/view/250278

Jiraporn Burakorn, Pran Pinthong and Montakan Aimkaew, Development of Healthy Whey Protein Drinks, Journal of Science and Technology, Ubon Ratchathani University. 24(1): 54-65, 2022. https://li01.tci-thaijo.org/index.php/sci_ubu/article/view/253067

Jiraporn Burakorn*, Pran Pinthong, Yuttapoom Sampantharak, Montakan Aimkaew and Kamonchanok Srithai, Quantification of Vanillin, Ethyl Vanillin and Methyl Vanillin Among Thai Rice Cultivars by Ultra-High Performance Liquid Chromatography-Tandem Mass Spectrometry, TRENDS IN SCIENCES. 21(3): 7252(1-8), 2024.

https://doi.org/10.48048/tis.2024.7252

Jiraporn Burakorn*, Pran Pinthong, Montakan Aimkaew, Pornprapa Tongbai and Kamonchanok Srithai. The Effect of Glucose Syrup on Rheological Properties of Sago Starch, TRENDS IN SCIENCES. 21(3): 7253(1-9), 2024.

https://doi.org/10.48048/tis.2024.7253

Jiraporn Burakorn, Pran Pinthong, Songporn Kraisit, Pornprapa Tongbai and Montakan Aimkaew, Use of Sago Starch and Konjac Powder in Boba Pearl, KKU Science Journal. 52(1): 067-068. 2024.

https://doi.org/10.14456/kkuscij.2024.7

Jiraporn Burakorn, Pran Pinthong, Songporn Kraisit, Montakan Aimkaew, Pimporn Plaichan and NattachaSiriwarin, Development of Madeleine Product by Partial Substitution of Wheat Flour with Tubtim Chumphae Rice Flour, Journal of Science and Technology, Ubon Ratchathani University. 27(1): 14-22, 2024.

https://li01.tci-thaijo.org/index.php/sci_ubu/article/view/261806

Jiraporn Burakorn, Pran Pinthong, Songporn Kraisit, Pimporn Plaichan, Nattacha Siriwarin and Montakan Aimkaew, Development of Khanom Arlua Product using Wheat Flour Partially Substituted with Tubtim Chumphae Rice Flour, KKU Science Journal. 52(2): 170-181, 2024.

https://doi.org/10.14456/kkuscij.2024.15

Jiraporn Burakorn, Pran Pinthong, Anurat Rammaphan, Pornprapa Tongbai, Montakan Aimkaew* and Nattacha Siriwarin, Effect of tapioca flour partial substitution with Chum Phae ruby rice flour on the characteristics of crackers, Bulletin of Applied Sciences. 13(2): 26-34, 2024. https://doi.org/10.60136/bas.v13.2024.1085

Jiraporn Burakorn, Pran Pinthong, Montakan Aimkaew and Nattacha Siriwarin, Development of instant Nam Prik Ong using freeze drying process, Journal of Food Research and Product Development (JFRPD). 54(2): 13-29, 2024.

https://kuojs.lib.ku.ac.th/index.php/JFRPD/article/view/5796/286

Jiraporn Burakorn, Pran Pinthong, Songporn Kraisit, and Nattacha Siriwarin, Development of crispy Sacha Inchi sheets, Journal of Food Research and Product Development (JFRPD). 54(2): 1-12, 2024.

https://kuojs.lib.ku.ac.th/index.php/JFRPD/article/view/5784/2868

Jiraporn Burakorn, Pran Pinthong, Songporn Kraisit, Nattacha Siriwarin, and Montakan Aimkaew, Effects of hot air drying on the physicochemical properties of fermented fish dip (Jaew Bong) with added cricket powder, J. Sci Technol MSU. 44(2): 115-12,. 2025.

https://li01.tci-thaijo.org/index.php/scimsujournal/article/view/261711/180243

Nattacha Siriwarin, Pran Pinthong, Montakan Aimkaew, Pimporn Plaichan and Noppawan Kladward, Effect of Different Extraction Methods on the Characteristics of Field Cricket (Gryllus bimaculatus) Powder, KKU Science Journal. 53(1): 101-111, 2025.

https://doi.org/10.14456/kkuscij.2025.8

☎️ 9. Contact Persons:

Mr. Pran Pinthong

Position : Head of Sensory Science Group, (Scientist, Senior Professional Level)

Email : pran@dss.go.th

Telephone : 0 2201 7419

Ms. Montakan Aimkaew

Position : Scientist, Practitioner Level

Email : montakan@dss.go.th

Telephone : 0 2201 7419

Ms. Nattacha Siriwarin

Position : Scientist

Email : nattacha@dss.go.th

Telephone : 0 2201 7419